Next: 5. Technology Up: Fabrication and characterization of Previous: 3. III-V compound semiconductor Contents

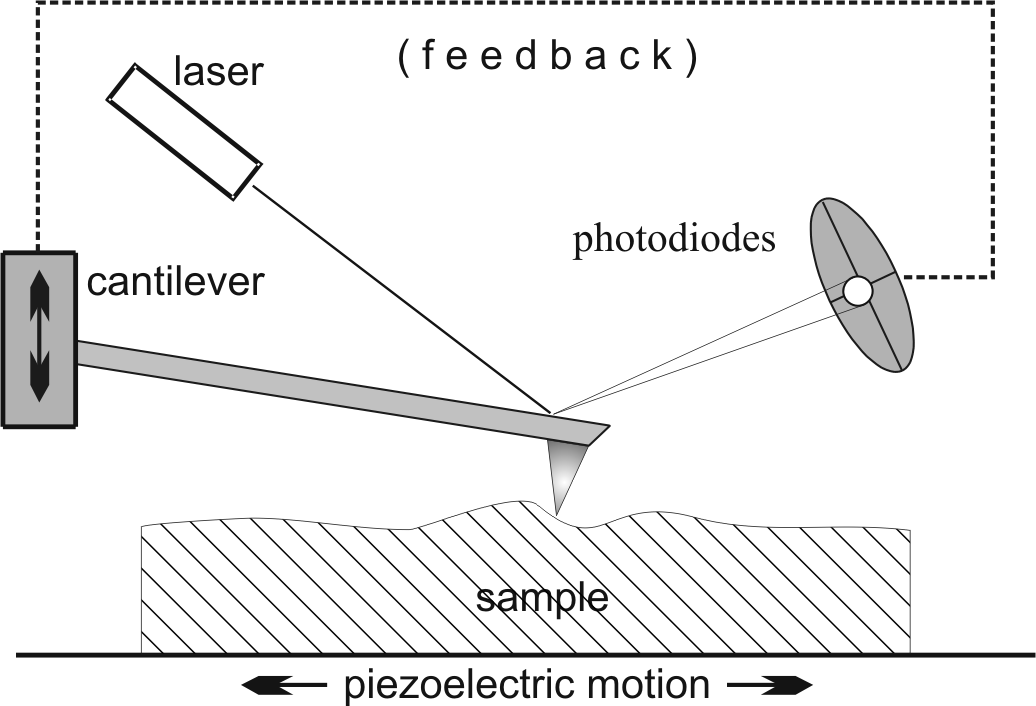

Atomic Force Microscopy technique provides three-dimensional

surface topographies at nm resolution of a wide range of solid

materials (conducting, insulating, magnetic). The basic principle

is simple: a sharp tip scans the sample surface detecting the

topography. Typical

![]() tips have a

curvature radius of 10-15 nm and opening angle of about

tips have a

curvature radius of 10-15 nm and opening angle of about ![]() . When the tip is brought very near to the surface to

be analyzed, it undergoes attractive or repulsive forces. The

cantilever, on which the tip is located, is deflected. An optical

amplification system measures the tip movements. Figure

4.1 shows the system working principle: a laser

beam points on the cantilever and four photodiodes in a cross

configuration detect the reflected beam. While the sample is

scanned, the tip-sample interaction is kept constant by feedback.

. When the tip is brought very near to the surface to

be analyzed, it undergoes attractive or repulsive forces. The

cantilever, on which the tip is located, is deflected. An optical

amplification system measures the tip movements. Figure

4.1 shows the system working principle: a laser

beam points on the cantilever and four photodiodes in a cross

configuration detect the reflected beam. While the sample is

scanned, the tip-sample interaction is kept constant by feedback.

|

Atomic Force Microscope has gone through many modifications for specific application requirements. There are several AFM operating modes: contact mode, tapping mode, phase imaging mode...

The first and foremost mode of operation, the contact

mode, is very similar to a profilometer: the tip-sample forces

are maintained at a constant level and with

piezoelectric motion, the surface is scanned by the tip.

The tapping mode, belongs to a family of AC modes, which

refers to the use of an oscillating cantilever. The tip

intermittently touches or taps the surface. The

natural resonance frequency is shifted by the tip-sample force.

The shift is proportional to the second derivative of the

corresponding potential. This information is then converted in a

topographical image of the surface. In order to filter out the

thermal noise, a lock-in amplification is introduced and a more

stable detection is

allowed.

In phase imaging mode, the phase shift of the oscillating

cantilever relative to the driving signal is measured. This phase

shift can be correlated with specific material properties, which

affect the tip/sample interaction.

The forces acting between the tip and the surface are of different

nature and depend on the tip-sample distance. The first

interaction is the electrostatic force. It begins at

![]() and may be either attractive or repulsive

depending on the material. At

and may be either attractive or repulsive

depending on the material. At

![]() , surface

tension effects result from the presence of condensed water vapor

at the surface. The tip is pulled down toward the sample surface

with attractive force up to

, surface

tension effects result from the presence of condensed water vapor

at the surface. The tip is pulled down toward the sample surface

with attractive force up to

![]() . Van Der Waals

forces appear at the angstrom level above the surface: the atoms

in the tip and sample undergo a weak attraction. Coming even

closer, electron shells from atoms on both tip and sample repulse

one another, preventing further intrusion by one material into the

other (Coulomb forces, contact mode). Pressure exerted

beyond this level leads to mechanical distortion and the tip or

the sample may be damaged.

. Van Der Waals

forces appear at the angstrom level above the surface: the atoms

in the tip and sample undergo a weak attraction. Coming even

closer, electron shells from atoms on both tip and sample repulse

one another, preventing further intrusion by one material into the

other (Coulomb forces, contact mode). Pressure exerted

beyond this level leads to mechanical distortion and the tip or

the sample may be damaged.

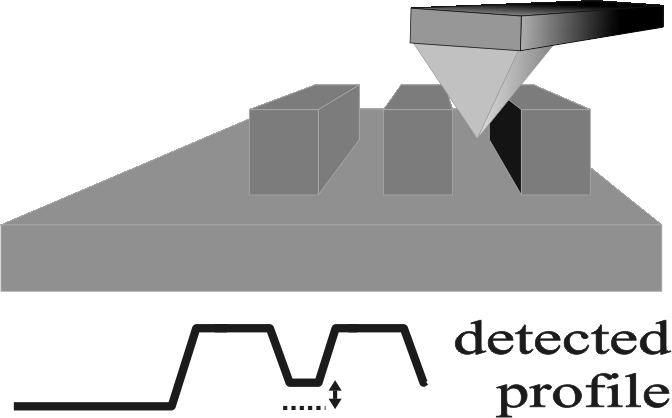

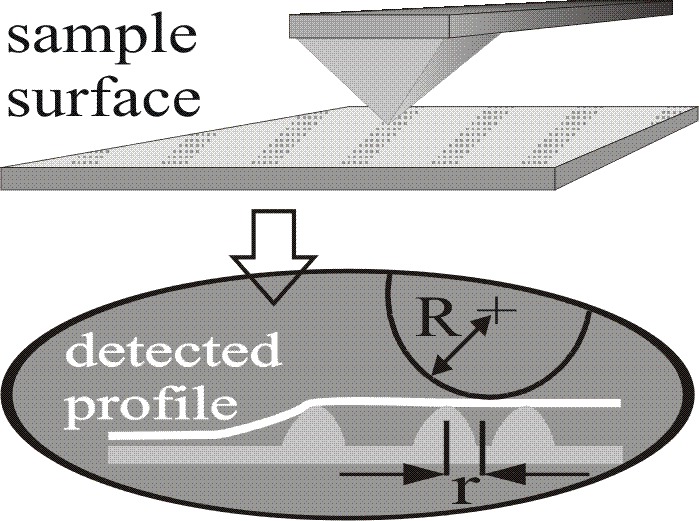

The actual sharpness of a tip influences directly its ability to resolve surface features. Moreover, certain tip damages (e.g. double-pointed and cracked tips) occur very often. In Fig. 4.2, the tip-sample geometry and interactions are considered. One obvious surface limitation is caused by deep grooves (Fig. 4.2(a)): the tip is not long enough, or thin enough, to reach the bottom of a recess. Furthermore, the tip cannot detect walls of the sample with an angle steeper than itself.

[]

[] |

After the air is pumped out from the column, an electron gun (at

the top) emits a beam of high energy electrons. Four different

sources can be used [Was03]: tungsten filament, ![]() crystal tip, Schottky emitter and the cold field emitter. In

ultra-high vacuum conditions (

crystal tip, Schottky emitter and the cold field emitter. In

ultra-high vacuum conditions (![]() mbar), the best beam

properties are supplied by cold field emitter. Schottky emitter is

a good compromise between performance and costs.

mbar), the best beam

properties are supplied by cold field emitter. Schottky emitter is

a good compromise between performance and costs.

The electron beam travels downward through a series of magnetic lenses designed to focus the electrons to a very fine spot. Near the bottom, a set of scanning coils deflect the focused beam back and forth across the specimen, row by row. The SEM images are normally rendered black and white.

Samples have to be prepared carefully to withstand the vacuum inside the microscope. Biological specimens are dried in a special way, which prevents them from shrivelling. Because the SEM illuminates them with electrons, they also have to be made to conduct electricity. Often SEM samples are coated with a very thin layer of gold by sputtering deposition.

The Hall effect measurement is a widely-used technique to determine electrical properties of semiconductors like majority carrier type, concentration and mobility. The Hall effect is based on the deflection by a magnetic field of moving charged particles.

In Figure 4.3, a rectangular sample has been

considered. A voltage

![]() and a magnetic field

and a magnetic field

![]() are applied. Electrons and holes flowing in the

semiconductor will experience a force, bending their trajectories,

and they will build up on one side of the sample, creating a

potential

are applied. Electrons and holes flowing in the

semiconductor will experience a force, bending their trajectories,

and they will build up on one side of the sample, creating a

potential

![]() across it (the so-called Hall

voltage). Assuming that all the conduction electrons have the

same drift velocity

across it (the so-called Hall

voltage). Assuming that all the conduction electrons have the

same drift velocity

![]() and the same

relaxation time

and the same

relaxation time ![]() , the resulting Lorentz force acting on

any electron is given by:

, the resulting Lorentz force acting on

any electron is given by:

where

![]() is the mobility.

Considering

is the mobility.

Considering

![]() and

and

![]() , the vector

equation 4.4 can be written as two scalar equations:

, the vector

equation 4.4 can be written as two scalar equations:

where

![]() is the conductivity and

relation 4.5 is just the Ohm's law. Equation

4.6 expresses the fact that, along the

is the conductivity and

relation 4.5 is just the Ohm's law. Equation

4.6 expresses the fact that, along the ![]() direction, the force on one electron due to the magnetic field

(

direction, the force on one electron due to the magnetic field

(

![]() ) is balanced by a force

(

) is balanced by a force

(

![]() ) due to the Hall field. (Eq. (4.6))

is generally written as

) due to the Hall field. (Eq. (4.6))

is generally written as

where

![]() is called the Hall

constant. For a p-type semiconductor, it can be shown that

is called the Hall

constant. For a p-type semiconductor, it can be shown that

| (4.8) |

with

![]() , where

, where ![]() is the

equilibrium concentration of holes in the sample. It is thus seen

that

is the

equilibrium concentration of holes in the sample. It is thus seen

that ![]() has a negative sign for electrons and a positive sign

for holes.

has a negative sign for electrons and a positive sign

for holes.

From 4.7, for a rectangular bar like in Fig. 4.3, the Hall constant and the Hall mobility can be expressed by:

where ![]() is the measured Hall voltage,

is the measured Hall voltage, ![]() is

the applied voltage along the length

is

the applied voltage along the length ![]() , and

, and ![]() is the

current. For a semiconductor with comparable concentrations of

electrons and holes,

is the

current. For a semiconductor with comparable concentrations of

electrons and holes, ![]() is given by

is given by

and for a highly ![]() -doped one to

-doped one to

In these two cases, the measurement of ![]() and

and

![]() determines the majority carrier concentration and the

mobility, respectively.

determines the majority carrier concentration and the

mobility, respectively.

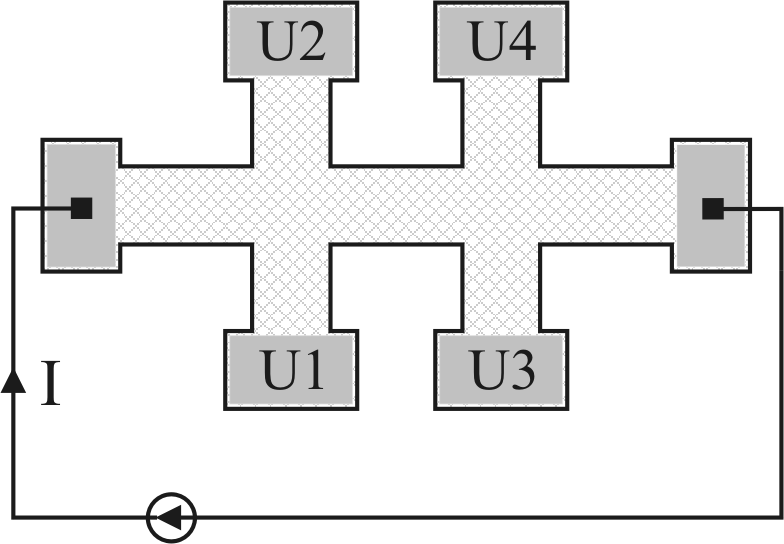

The simplest arrangement for measuring the Hall voltage is the

rectangular geometry shown in Fig. 4.3, but a

number of spurious voltages is included in this measurement. All

these spurious voltages are eliminated if four readings are taken

by reversing the direction of the bias current ![]() and the

magnetic flux

and the

magnetic flux ![]() . The true Hall voltage is then obtained by

taking the average of the four readings. The contacts used for

measuring the Hall voltage in Fig. 4.3 should be

infinitesimally small, so that they do not distort the current

flow. The bridge shaped samples shown in Fig. 4.4(a)

are often used to reduce the distortion of the current. The ears

on the pattern allow a large area to be used for contacting the

sample without a severe distortion of current flowing through the

specimen. The Hall voltage is measured between contacts 1 and 2,

and then between 3 and 4. The average is taken as a final value.

. The true Hall voltage is then obtained by

taking the average of the four readings. The contacts used for

measuring the Hall voltage in Fig. 4.3 should be

infinitesimally small, so that they do not distort the current

flow. The bridge shaped samples shown in Fig. 4.4(a)

are often used to reduce the distortion of the current. The ears

on the pattern allow a large area to be used for contacting the

sample without a severe distortion of current flowing through the

specimen. The Hall voltage is measured between contacts 1 and 2,

and then between 3 and 4. The average is taken as a final value.

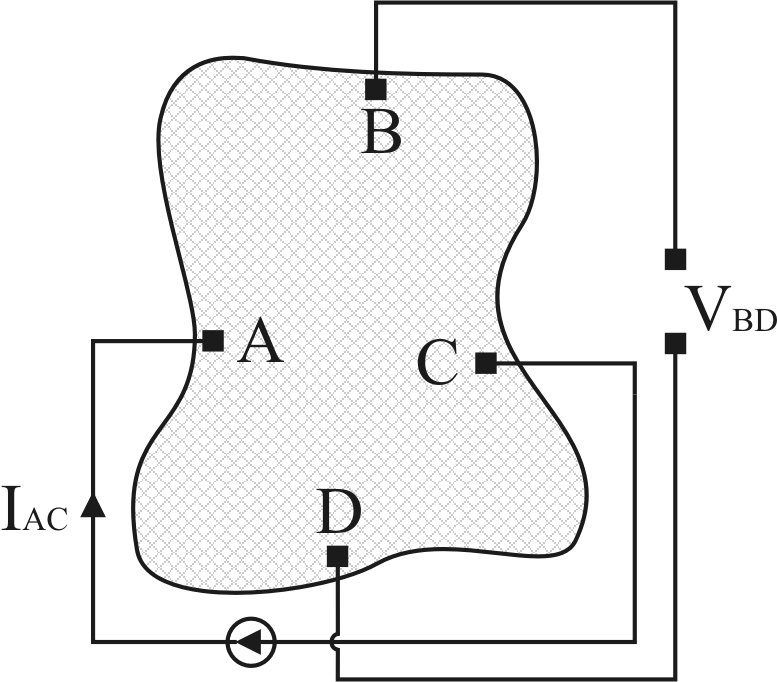

[Van der Pauw arrangement for an arbitrary shaped sample.]

[Van der Pauw arrangement for an arbitrary shaped sample.] |

In some cases, it may not be convenient to cut the specimen in the

form of a rectangular bar. Van der Pauw [vdP58] suggested an

interesting method, using an arbitrary shaped thin-flat sample.

The above sample (simply connected, i.e., no holes or

nonconducting islands or inclusions), contains four very small

ohmic contacts placed on the sample periphery (preferably in the

corners). In presence of a normal magnetic field to the sample

surface, a current ![]() is established between two opposite

contacts (a and c), and the voltage is measured between the other

ones (b and d), as shown in Figure 4.4(b).

is established between two opposite

contacts (a and c), and the voltage is measured between the other

ones (b and d), as shown in Figure 4.4(b).

The resistance, defined as:

|

(4.14) |

A different way to determine the background concentration ![]() of carriers in a semiconductor, is the capacitance-voltage (C-V)

measurement. The C-V method relies on the fact that the width of a

reverse biased space charge region of a junction depends on the

applied voltage. The space charge

of carriers in a semiconductor, is the capacitance-voltage (C-V)

measurement. The C-V method relies on the fact that the width of a

reverse biased space charge region of a junction depends on the

applied voltage. The space charge ![]() per unit area of the

semiconductor junction under an applied bias V is:

per unit area of the

semiconductor junction under an applied bias V is:

In the case of uniform doping concentration, ![]() is

constant within the depletion region and a strait line should be

obtained by plotting

is

constant within the depletion region and a strait line should be

obtained by plotting ![]() versus V. The intercept on the X-axis

of the line represents

versus V. The intercept on the X-axis

of the line represents ![]() , the built-in potential4.1. If

, the built-in potential4.1. If

![]() is not constant, the doping profile can be determined from

the slope of the curve and equation 4.20.

is not constant, the doping profile can be determined from

the slope of the curve and equation 4.20.

| (4.23) | |||

| (4.24) |

|

(4.25) | ||

|

(4.26) |

In Fig. 4.6, the measured resistances are

plotted as a function of the distance ![]() . Fitting

Eq. (4.22), the values of

. Fitting

Eq. (4.22), the values of ![]() and

and ![]() can be obtained.

can be obtained.

|

(4.27) |

|

(4.28) |

|

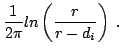

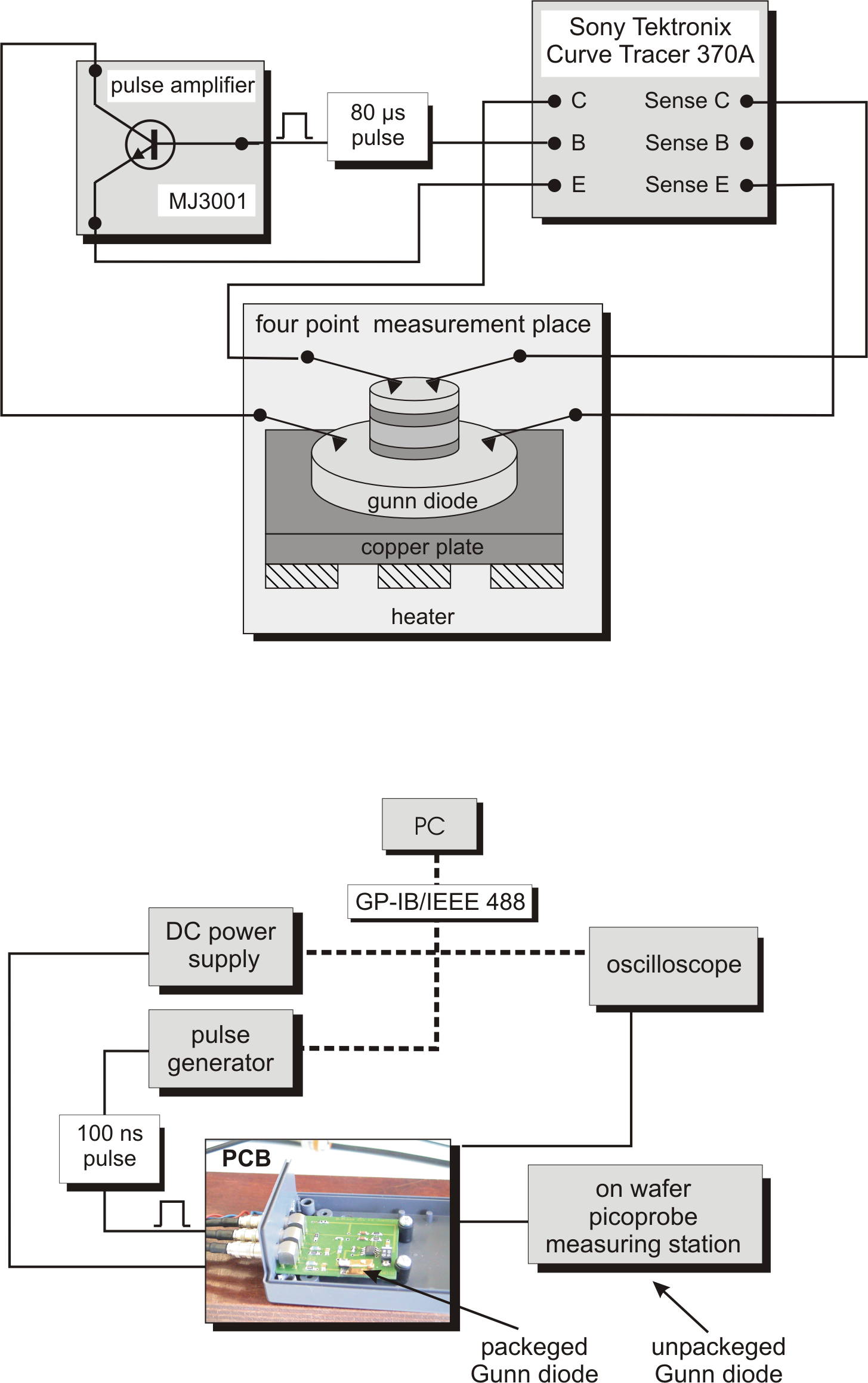

The study of the breakthrough voltage without damaging the Gunn

diode requires DC measurements with very short pulses (

![]() ). Moreover, with different pulse length, the

influence of the diode selfheating on the I-V characteristics can

be determined. For these two reasons, a

). Moreover, with different pulse length, the

influence of the diode selfheating on the I-V characteristics can

be determined. For these two reasons, a

![]() measurement setup has been designed and realized [Pro04]. The

principle scheme of the measurement set-up is presented in

Fig. 4.7(bottom).

measurement setup has been designed and realized [Pro04]. The

principle scheme of the measurement set-up is presented in

Fig. 4.7(bottom).

100 ns pulses are generated from a low-power pulse generator and

are amplified by a custom-designed printed circuit board (PCB),

powered by a computer controlled DC power supply. The pulses are

forwarded to the terminal of the diodes. The short pulse length

requires a special attention in the terminal connection, in order

to avoid line reflections. Therefore, on-wafer measurements are

performed with HF picoprobes. For the packaged diodes, a further

custom adaptor is connected directly to the PCB. The voltage drop

on the diode and on a known serial resistance within the PCB are

measured with a digital oscilloscope. The serial resistance

voltage drop is proportional with the current flowing through the

diode. The sweep range of the voltage pulse can be tuned from

![]() up to

up to

![]() and the current is limited

to

and the current is limited

to

![]() . A HP-VEE program running on a PC controls

the measurements through a IEEE488 interface bus and computes the

diode DC characteristics from the oscilloscope raw data.

. A HP-VEE program running on a PC controls

the measurements through a IEEE488 interface bus and computes the

diode DC characteristics from the oscilloscope raw data.

Temperature dependent measurements have been more complicated and

time consuming: they have required to build a compact custom-made

temperature controller based on a peltier element and a PT100

thermosensor. The temperature is function of the resistance of the

PT100, which is embedded in a flat copper block. The peltier

element cools or heats (depending on the terminal polarity) the

copper block, transferring the heat to or from a big metal

reservoir, kept at room temperature. In the considered setup, the

sample is fixed with vacuum on the copper block and the

temperature can be tuned from 2

![]()

![]() C up to

C up to ![]() C. Lower

temperatures can not be reached because of ice formation and

higher ones could damage the HF picoprobes.

C. Lower

temperatures can not be reached because of ice formation and

higher ones could damage the HF picoprobes.

When making on-wafer measurements, an ongoing concern is how accurate and repeatable are the collected data. The hardware has to be as good as practically possible, balancing performance and costs; error corrections can be an useful tool to improve measurement accuracy. The basic source of measurement errors are:

Before a network analyzer can make error-corrected measurements, the network analyzer systematic errors must be measured and removed. Calibration is the process of quantifying these errors by measuring known precision standards. Three techniques are commonly used to calibrate network analyzers and wafer probing stations:

The LRRM4.2, a variation of LRM, was used for most of the measurements with the HP8510C-XF vector network analyzer in Figure 4.8; it was usually software assisted by WinCal, a program developed by Cascade Microtech, which supplied also the picoprobes and the probing station.

During HF measurements and after data has been collected, it is essential to have an overview over the produced results. The fastest way is to display data with some kind of graphical interfaces (normally integrated in the measurement system or in a software package for computer controlled measurement systems). The most popular diagram for each parameter are:

Smith chart represents the standard for

The Smith Chart is derived from the relationship between

complex reflection coefficient ![]() and complex impedance Z.

and complex impedance Z.

Writing the impedance and the reflection coefficient as

function of the real and imaginary components, ![]() and

and

![]() , equation 4.29 is equivalent

with:

, equation 4.29 is equivalent

with:

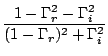

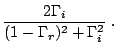

|

(4.30) | ||

|

(4.31) |

To actually see the form of the equations for deriving the Smith Chart, we rearrange the terms to obtain the equations for a set of circles:

From equations 4.32 and 4.33 the Smith Chart can be easily drawn. Some key features of this chart (Fig. 4.9) are listed:

imone.montanari(at)tiscali.it 2005-08-02